- Metal Processing Machinery Parts[6]

- Cast & Forged[6]

- Magnetic Materials[6]

- Cleaning Equipment Parts[6]

- Carbon[3]

- Ceramics[3]

- Keyboards[1]

- Slide Switches[4]

- Marble[1]

- Tool Parts[6]

- Used Embroidery Machines[2]

- Catalyst[2]

- Home Textile Product Machinery Parts[1]

- Solar Cells[29]

- Pigment[3]

- LED Lamps[2]

- Transformers[6]

- Refractory[21]

- Voltage Regulators/Stabilizers[3]

- Instrument Parts & Accessories[1]

- Golf[1]

- Steel Pipes[2]

- Building Glass[6]

- Living Room Furniture[10]

- Metallurgy Machinery[7]

- Metal Coating Machinery[3]

- Electrical Ceramics[11]

- Surgical Instruments[1]

- Other Metals & Metal Products[6]

- Steel Round Bars[3]

- Other Mechanical Parts[2]

- Other Steel Products[3]

- Flat Steel[1]

- Milling Cutter[1]

- Other Cutting & Forming Tools[1]

- Other Stainless Steel[2]

- Oxide[2]

- Temperature Instruments[2]

- Other Accessories[4]

- Copper Wire[1]

- Welding Wires[6]

- Other Metallurgy Machinery[6]

- Rolling Mill[1]

- Other Metal Processing Machinery[1]

- Chemical Process Equipment Parts[2]

- Other Petrochemical Related Products[1]

- Dental Equipments[1]

- Other Chemicals[1]

- Adhesives & Sealants[1]

- Contact Person : Ms. Yu Amy

- Company Name : Advanced Technology & Materials Co., Ltd.

- Tel : 0086-10-62182822

- Fax : 0086-10-62182325

- Address : Beijing,Beijing,No.76 Xueyuan Nanlu,Haidian

- Country/Region : China

- Zip : 100081

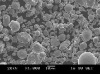

Stainless steel powder

Applying ultra-high water-atomization and restriction gas-atomization technology, AT&M can not only produce standard metal powder for PM but super-fine powder with particle size less than 10 um. The final products made from the metal powder are widely used in the industrial field like medical equipment, office equipments and consumables, automobile, hard wear, sports facility, clock and watch. . .

Characteristics

-Fine particle size -Optimum particle size

-High density, high purity -Low density, high purity

-Low oxygen content -Low oxygen content

-Controlled particle size distribution for MIM and Porous Products

Typical powder properties for MIM

Grade | Shape | S.D. (g/cm3) | T.D. (g/cm3) | O.C PPM | Mean particle Size(μm) |

D50 | |||||

316L | Spheroidal | 7.6-7.9 | >4.2 | <3000 | 9~11 |

17-4PH | Spheroidal | 7.6-7.9 | >4.2 | <3000 | 9~11 |

430L | Spheroidal | 7.6-7.9 | >4.2 | <3000 | 9~11 |

Typical powder properties for porous material

Grade | Shape | A.D. (g/cm3) | O.C PPM | Particle Size(mesh)

|

316L | Irregular | 1.8-2.3 | <2800 | -80+150, -150+250, -250+500, -150+325 variety of particle size |

304L | Irregular | 1.8-2.3 | <2800 | |

430L | Irregular | 1.8-2.3 | <3000 | |

410S | Irregular | 1.8-2.3 | <3000 | |

904 | Irregular | 1.8-2.3 | <3000 | |

17-4PH | Irregular | 1.8-2.3 | <3000 |

Other alloys and tailored particle size distributions, not listed, are available on request.

Stainless steel powder