- Metal Processing Machinery Parts[6]

- Cast & Forged[6]

- Magnetic Materials[6]

- Cleaning Equipment Parts[6]

- Carbon[3]

- Ceramics[3]

- Keyboards[1]

- Slide Switches[4]

- Marble[1]

- Tool Parts[6]

- Used Embroidery Machines[2]

- Catalyst[2]

- Home Textile Product Machinery Parts[1]

- Solar Cells[29]

- Pigment[3]

- LED Lamps[2]

- Transformers[6]

- Refractory[21]

- Voltage Regulators/Stabilizers[3]

- Instrument Parts & Accessories[1]

- Golf[1]

- Steel Pipes[2]

- Building Glass[6]

- Living Room Furniture[10]

- Metallurgy Machinery[7]

- Metal Coating Machinery[3]

- Electrical Ceramics[11]

- Surgical Instruments[1]

- Other Metals & Metal Products[6]

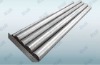

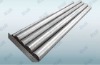

- Steel Round Bars[3]

- Other Mechanical Parts[2]

- Other Steel Products[3]

- Flat Steel[1]

- Milling Cutter[1]

- Other Cutting & Forming Tools[1]

- Other Stainless Steel[2]

- Oxide[2]

- Temperature Instruments[2]

- Other Accessories[4]

- Copper Wire[1]

- Welding Wires[6]

- Other Metallurgy Machinery[6]

- Rolling Mill[1]

- Other Metal Processing Machinery[1]

- Chemical Process Equipment Parts[2]

- Other Petrochemical Related Products[1]

- Dental Equipments[1]

- Other Chemicals[1]

- Adhesives & Sealants[1]

- Contact Person : Ms. Yu Amy

- Company Name : Advanced Technology & Materials Co., Ltd.

- Tel : 0086-10-62182822

- Fax : 0086-10-62182325

- Address : Beijing,Beijing,No.76 Xueyuan Nanlu,Haidian

- Country/Region : China

- Zip : 100081

Tungsten alloy for radiation shielding

Detailed Product Description

ABOUT PRODUCT

Gamma radiation and X-rays are absorbed most effectively byhigh-density materials. AT&M high-density materials are a family oftungsten-based materials with densities 50% greater than that of lead.The high-density, good mechanical strength and excellent machinabilityof AT&M materials make them ideal for shielding applications. A varietyof sizes and shapes are available.

Property:

Tungsten content(wt%): 90-97

High density 16.0~18.5g/cm3

High strength 580~950Mpa

Good plastic

Good corrosion-resistant

Good machining property

High thermal conductivity

Low coefficient of thermal expansion

high mass absorption coefficient

Application:

Kinetic energy penetrators

Counterweights in aircraft and ship applications

Gyroscope rotors

Flywheel rim

Governors

Radiation shielding

Specifications:

Maximum Size:φ550×1300mm

ABOUT PLANT

Refractory metal and ceramics planthas been developing from Refractory Alloy Research Department of CISR(Central Iron & Steel Research Institute) founded in 1958. As one ofthe earliest unit engaged in refractory metal research and production inChina,over the past 50 years, more than 250 research projects have beendone and 58 great achievements have been made including 9 national inventions,40 metallurgy ministry awards and 21 national patents. Now weare at the top-level in refractory metal and ceramic material researching and producing within more than 300 sets of advanced production equipments and 20 sets of testing facilities.

AT&M Refractory Plant is ISO9001:2000 certified.

ABOUT EQUIPMENTS

The main equipments include:

Φ1250×2300mm cold and hot isostatic pressing achine;

Tmax=2,400 high temperature sintering furnaces;

large-scale vacuum sinteringfurnaces;

Large infiltration furnaces for metal and metal ceramic composites;

Tmax=2000 high temperature tensile strength tester;

Ultrasonic crack detector;

Laser thermal conductivity tester;

laser powder particle size tester.

ANNUAL CAPACITY

The annual production capacity is more than 600 tons of tungsten and molybdenum products.

ABOUT ALICE Project of CERN

CERN is the European Organization for Nuclear Research, the world's largest particle physics centre. AT&M was proud of supplying the Tungsten Heavy Alloy for the Accelerations and Detectors. CERN awarded AT&M the excellent supplier for the best quality and good service.