- Metal Processing Machinery Parts[6]

- Cast & Forged[6]

- Magnetic Materials[6]

- Cleaning Equipment Parts[6]

- Carbon[3]

- Ceramics[3]

- Keyboards[1]

- Slide Switches[4]

- Marble[1]

- Tool Parts[6]

- Used Embroidery Machines[2]

- Catalyst[2]

- Home Textile Product Machinery Parts[1]

- Solar Cells[29]

- Pigment[3]

- LED Lamps[2]

- Transformers[6]

- Refractory[21]

- Voltage Regulators/Stabilizers[3]

- Instrument Parts & Accessories[1]

- Golf[1]

- Steel Pipes[2]

- Building Glass[6]

- Living Room Furniture[10]

- Metallurgy Machinery[7]

- Metal Coating Machinery[3]

- Electrical Ceramics[11]

- Surgical Instruments[1]

- Other Metals & Metal Products[6]

- Steel Round Bars[3]

- Other Mechanical Parts[2]

- Other Steel Products[3]

- Flat Steel[1]

- Milling Cutter[1]

- Other Cutting & Forming Tools[1]

- Other Stainless Steel[2]

- Oxide[2]

- Temperature Instruments[2]

- Other Accessories[4]

- Copper Wire[1]

- Welding Wires[6]

- Other Metallurgy Machinery[6]

- Rolling Mill[1]

- Other Metal Processing Machinery[1]

- Chemical Process Equipment Parts[2]

- Other Petrochemical Related Products[1]

- Dental Equipments[1]

- Other Chemicals[1]

- Adhesives & Sealants[1]

- Contact Person : Ms. Yu Amy

- Company Name : Advanced Technology & Materials Co., Ltd.

- Tel : 0086-10-62182822

- Fax : 0086-10-62182325

- Address : Beijing,Beijing,No.76 Xueyuan Nanlu,Haidian

- Country/Region : China

- Zip : 100081

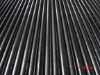

superalloy bar

The Fine Metal Branch of AT&M has the ability to produce master alloy bars of casting superalloys and strips of deforming superalloys,till now,we have a R&D and producing history of more than 50years in superalloy industry.

At present, we have produced the following casting master alloys: K417(IN100), K403, K4169(Inconel718C), K418(INCO713C),K640(X40),DZ40M(DSX40) etc. and the following deforming superalloys: Inconel601, Inconel800, Inconel800H, Inconel718,Rene41,Waspalloy,C263,A286,HA188,GH95 etc.

Product type:Fe-based superalloy,Ni-based superalloy,Co-based superalloy.

We can provide different shape products,like superalloy bar,superalloy rod,superalloy wire,superalloy ingot,superalloy strip,superalloy plate,superalloy tube,etc.

Superalloy is one of our main products. We have a lot of co-operating with foreign companies. Our goal is to produce superalloy materials of specification and designation needed by customers.

Introduction about superalloy:

Superalloys are important metal materials used for hot end parts of modern aerospace turbines, high temperature parts of rocket turbines and equipment in field of energy, metallurgy and chemistry. They can be used under conditions of higher stress, high temperature (600-1100) oxidization atmosphere, combustion and corrosion. According to base element, Superalloys are divided into Fe-base, Ni-base and Co-base alloys. According to formation process, superalloys are divided into deformation alloy, precision casting alloy and powder alloy. The main requirements of superalloy properties are heat-stability, heat-strength and texture stability.

Generally, superalloys are used in combustion chamber, force-added combustion chamber, directional blade, turbine blade and turbine disc. The typical materials used in combustion chamber and force-added combustion chamber are GH3030, GH3039, GH1140, GH333, GH2018, GH42, GH3044, GH3218, GH170, GH163 etc. Directional blade material is mainly casting alloys; the typical alloys are K32, K14, K38, K3, K5, K17, K19, K002, K20 etc. Turbine blade material is mainly age-hardening deforming alloys and casting alloys. The typical working blade material is GH4033, GH2302, GH143, GH4049, GH151, GH118, GH220, K417, K419 etc.

Product of ATM for example:

718 | Nickel alloy precipitation hardened by gamma prime and double prime. Readily fabricated, weldable even in the hardened condition. Used for gas turbine components to 1200°F, as well as for cryogenic equipment. | |||||||||||

| Composition | Inventory | ||||||||||

| Cr | Ni | Mo | Co | Al | Ti | Other | Plate | Sheet | Bar | Welding Product |

|

| 19 | 52 | 3 | - | 0.5 | 0.9 | Cb: 5 | X | X | X | X |

|

|

| |||||||||||

| Product Form | ASME | ASTM | AMS | UNS |

| ||||||

| Sheet, Plate |

| B 670 | 5596 |

|

| ||||||

| Bar | SB-637 | B 637 | 5662 |

|

| ||||||

| Wire |

|

| 5832 |

|

|

| |||||

superalloy bar